Waste-Spark-Ignition System: Companion Cylinders

Waste-Spark-Ignition System:

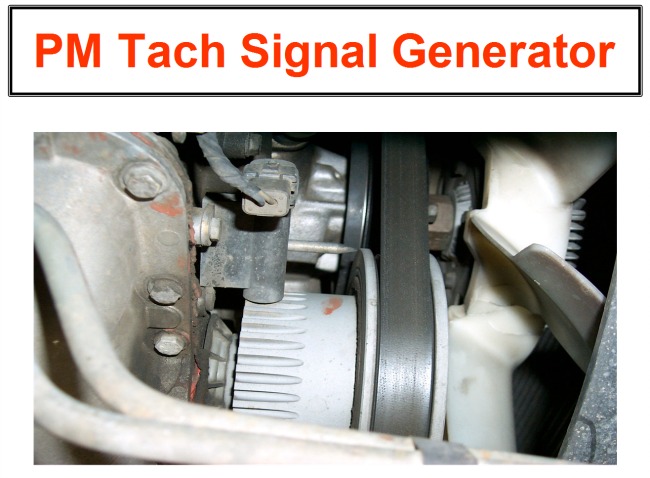

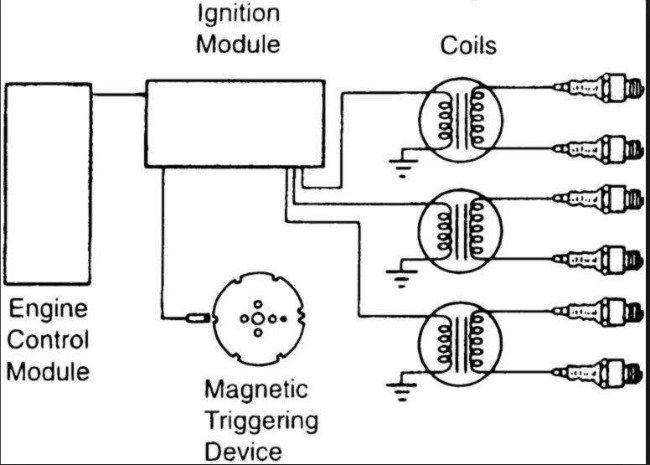

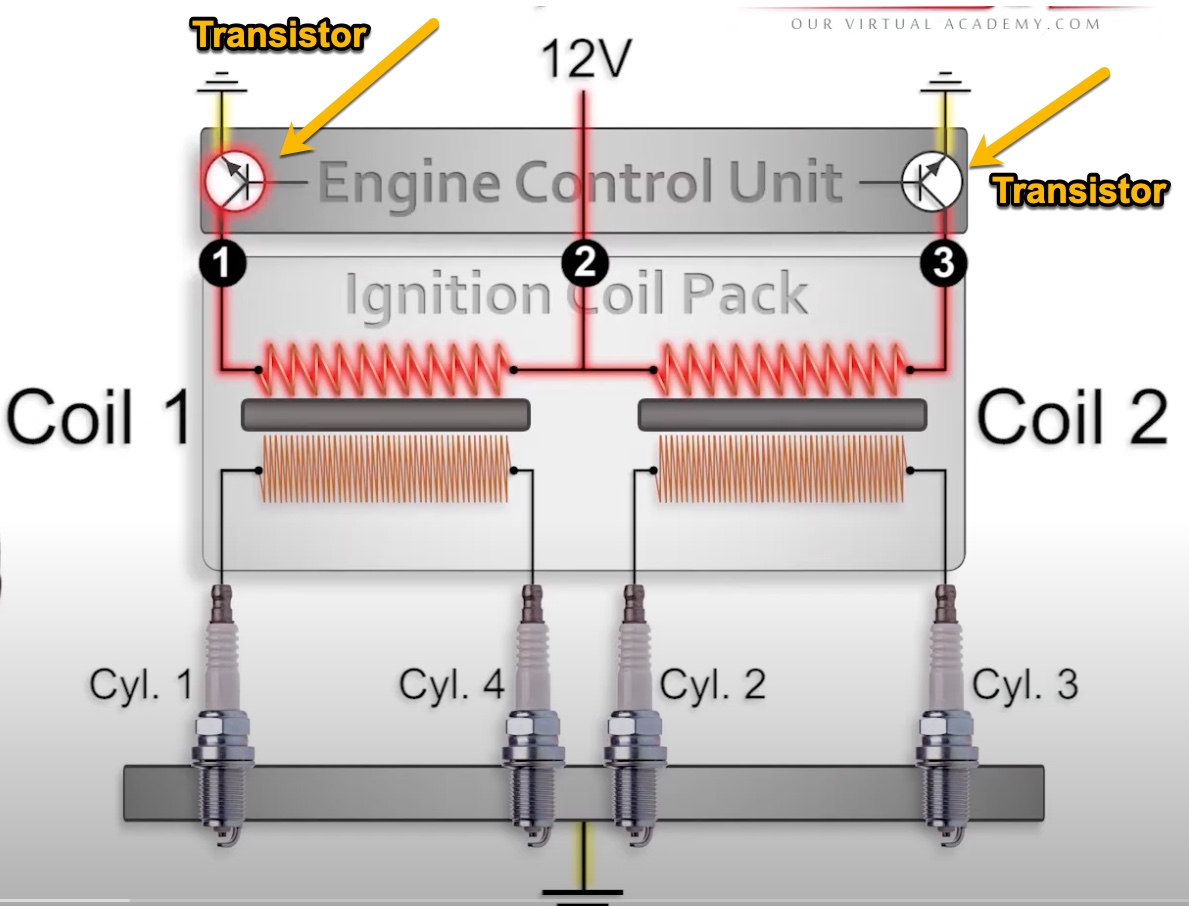

On waste spark systems or distributor-less ignition system, the ignition control module receives an engine position signal or RPM signal to fire the ignition coils.

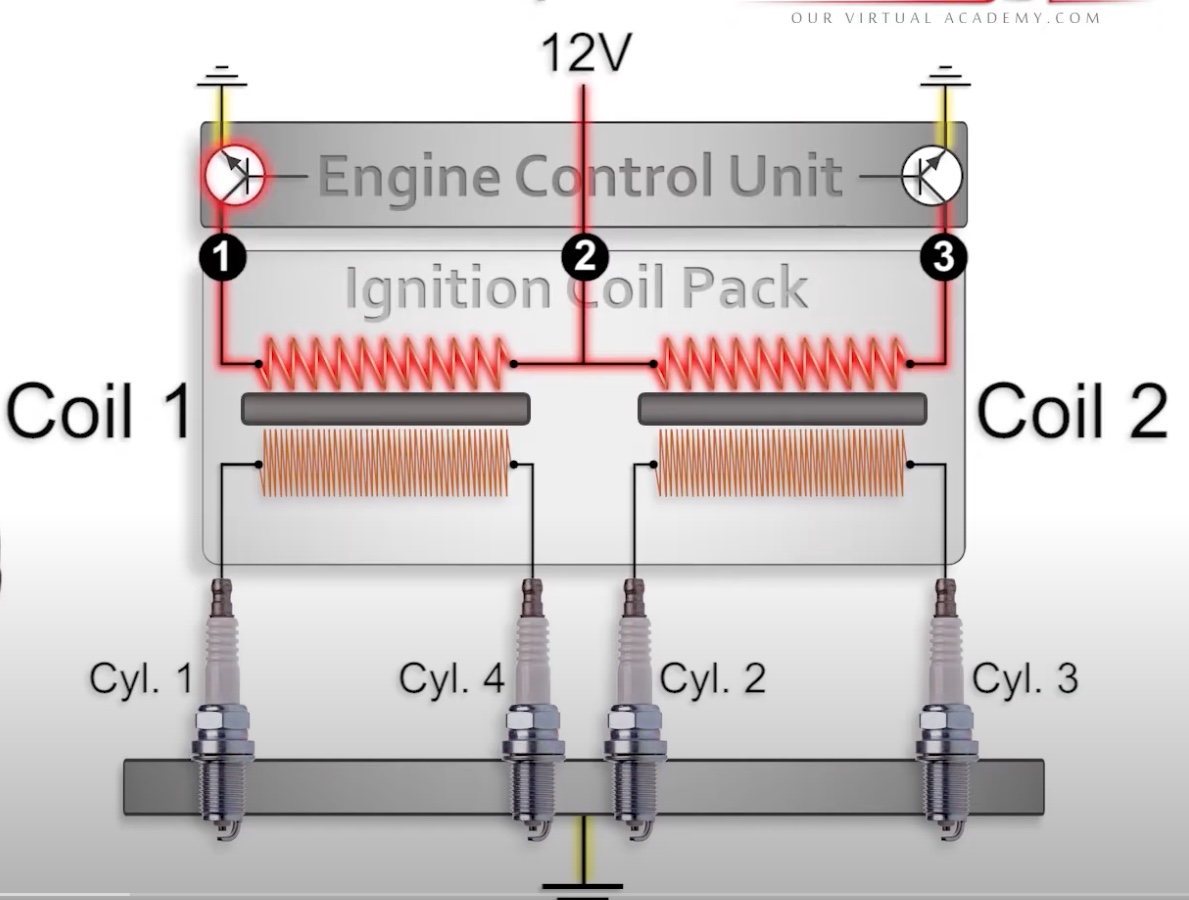

The ignition coils are will have battery voltage supplied to them and a control ground circuit through an Ignition Control Module (ICM) or Power-Train Control Module (PCM) by using three internal NPN transistors.

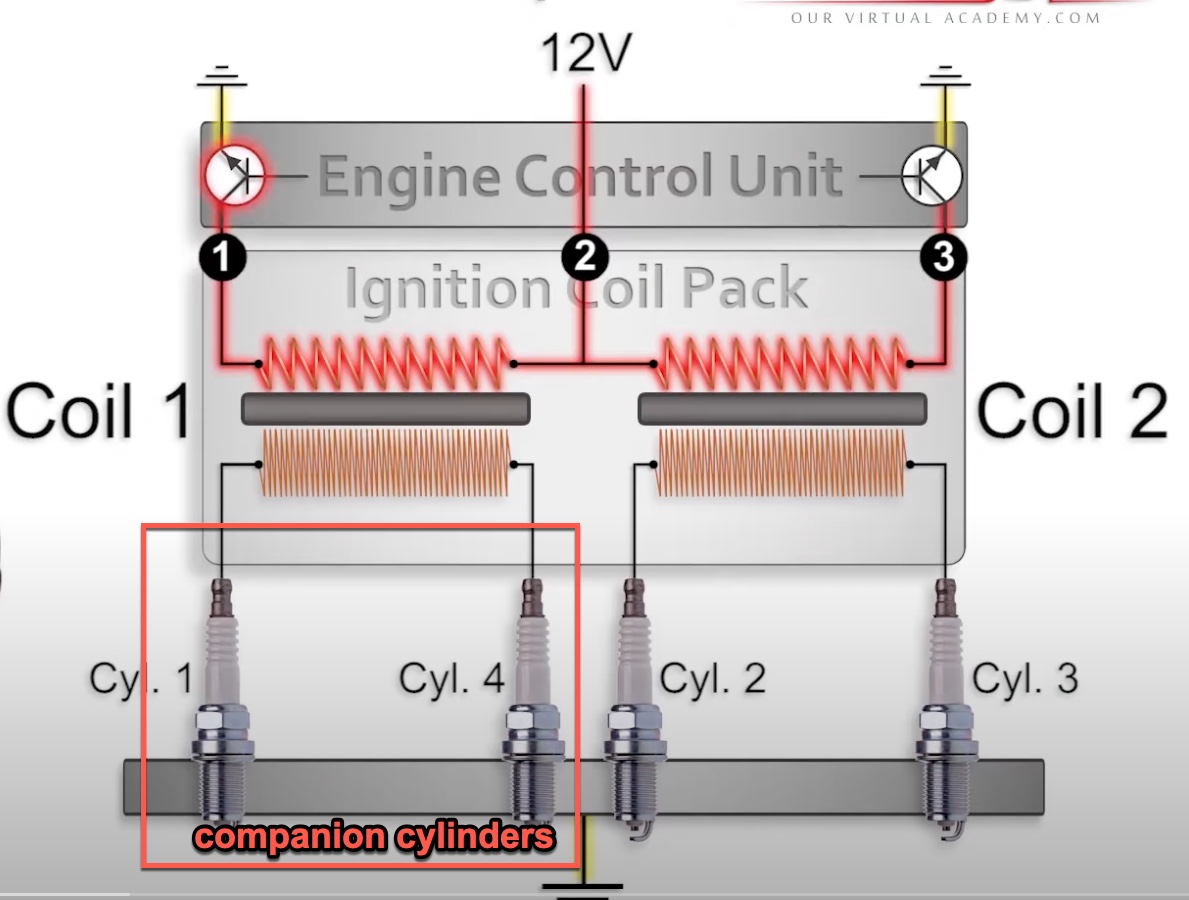

There are two coils that fire at the same time.

Coil is paired to the engine so the spark plugs from each ignition coil are in companion cylinders

Imagine by Tech Help Training : www.tec-help.com

Top Dead Center Compression verses Top Dead Center Exhaust are separated by each cylinder's intake and exhaust valves position and operation

Waste-Spark-Ignition System

Waste-Spark-Ignition

Each pair of cylinders will be fired by the same ignition coil. One cylinder will fire on the compression stroke "event" and the companion cylinder will fire at Top Dead Center on the exhaust stroke also know as "waste spark".

Resistance determines the voltage requirements for each cylinder. The cylinder on Top Dead Center Compression will have higher resistance which requires a higher voltage to ionize the spark plug gap, than its companion cylinder on TDC exhaust.

Illustration on waste Spark Companion Cylinders

High resistance is caused by the Air Fuel Ratio "rich or lean" along with high pressures within the cylinder on Top Dead Center Compression.

The cylinder on top dead center exhaust will have inert gases along with very low pressure requiring much less voltage to ionize the spark plug gap.

Waste-Spark-Ignition

Remember the PCM will ground the ignition coil's primary windings, while increasing current flow and a magnetic field, charging the coils primary circuit.

Waste-Spark-Ignition

When the Powertrain Control Module "PCM" or the Ignition Control Module "ICM" releases the ground the ignition coil will fire.

Also, any unwanted resistance in the circuit will affect the ignition coils operation and the vehicle's performance.

Waste-Spark-Ignition: Current Ramping

Waste-Spark-Ignition

Using an amp probe to check the primary ignition is also a good technique.

By using an amp probe you can see the integrity of the primary electrical circuit.

This accomplished by watching the current ramp of the electrical circuit and the measurement of amperage going through the circuit dynamically / under a load.

In my opinion is the best way to test any electrical coil.

Using an amp probe wrapped around either the positive or negative wire, "never both" will give you a good idea of how the primary ignition circuit is working.

There is a mini test associate with this video

Imagine by Tech Help Training : You can use you manual as reference from the zoom update class

CLASS SCHEDULES

Emission Control 1:

B.A.R. Smog Check

Inspector Level 1

(Inspector "Smog" License):

Engine Fundamentals

8am - 12:15 pm

Summer Class

7/5/2022 -8/5/2022

Class # 799065

Emission Control 2:

B.A.R. Smog Check

Inspector Level 2

(Inspector "Smog" License):

Rules and Regulations

8am - 12:15 pm

Summer Classes

7/5/2022 - 8/5/2022

Class # 799067

Engine Performance 1:

8am - 12: 15 pm

Date: TBD

Class # 799069

Engine Performance 2:

B.A.R. Specified Diagnostic

and Repair Training

(Repair "Smog" License)

Time: TBD

Date: TBD

Class # 799071

Emission Control 1

(Inspector "Smog" License):

5:00pm - 8:45 pm

Date: TBD

Class # 799065

Emission Control 2:

(Inspector "Smog" License):

5:00pm - 8:45 pm

Date: TBD

Class # 799065

Exhaust Emissions (Update Class):

5:30 pm - 8:45 pm

Tuesday nights:

Dates: coming soon

Class # 796070